Contrary to popular belief, your circular saw blade is not fit to be used for all materials and jobs. They are designed specially to suit certain job profiles.

All-purpose blades are available in the market, but they are unable to deliver results as fine as those by specialized blades. In such a scenario, being aware of certain fundamental information may help you make the right choice.

-

Types of blade

The specialized ones are a good investment as they deliver the best results possible for a job that they are meant for. They also help reduce downtime by increasing the efficiency of each cut. Here are some of the frequently used and easily available blade types.

Crosscutting Blade

These are meant for cutting wood, against the grain.

Ripping blades

They are also meant to be used on wood but in the direction of the grain. Do remember to not use them when working with plywood.

They are also meant to be used on wood but in the direction of the grain. Do remember to not use them when working with plywood.

Combination blades

These are good for versatile use. They also help to reduce downtime while working

by eliminating the need for frequent changes.

Metal-Cutting blades

They are designed with hard metals to cut easily through other hard metals in turn.

Nail cutting blades

These should be used when wood with nails or similar objects needs to be cut.

Abrasive blades

You can use them for masonry projects. They also work well with metals.

Dry diamond blades

It works best on hard and brittle materials like masonry and tiles.

Fine-Tooth Finish Blades

For projects that need a very fine finish to the cuts, the ideal choice of the blade should be a fine-tooth finish blade.

The paneling blade

Use them for flooring projects as well as for cutting veneer, laminates, plywood, and other similar light-gauge materials.

Dado blades

They are ideal for making groove cuts in the wood; However, they ought to be used only in the radial arm and table saws.

-

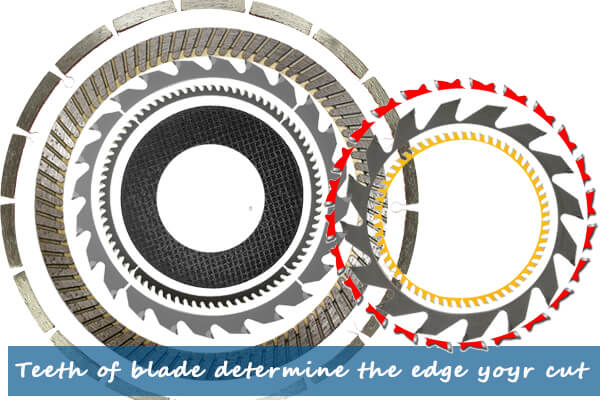

Nature of teeth

The teeth of a blade are the secret to its performance and are optimized for performing specific functions. A blade with more teeth will be capable of making finer and cleaner cuts than one with lesser teeth. The latter can be desirable for projects that require the quick removal of material, without clogging either the wood or the blade. It is especially useful in projects where lengthwise cuts need to be made.

The angle at which the teeth are positioned also determines their performance. They can be positive, negative, or neutral. An acute positive angle is good for removing material faster and making quick cuts. However, it causes a lot of tears out. A negatively angled blade is the exact opposite.

Remember, the choice of the blade depends entirely on your project type. It is important to assess your project needs beforehand and equipped with this information, you should be able to pick just the right blade for yourself.